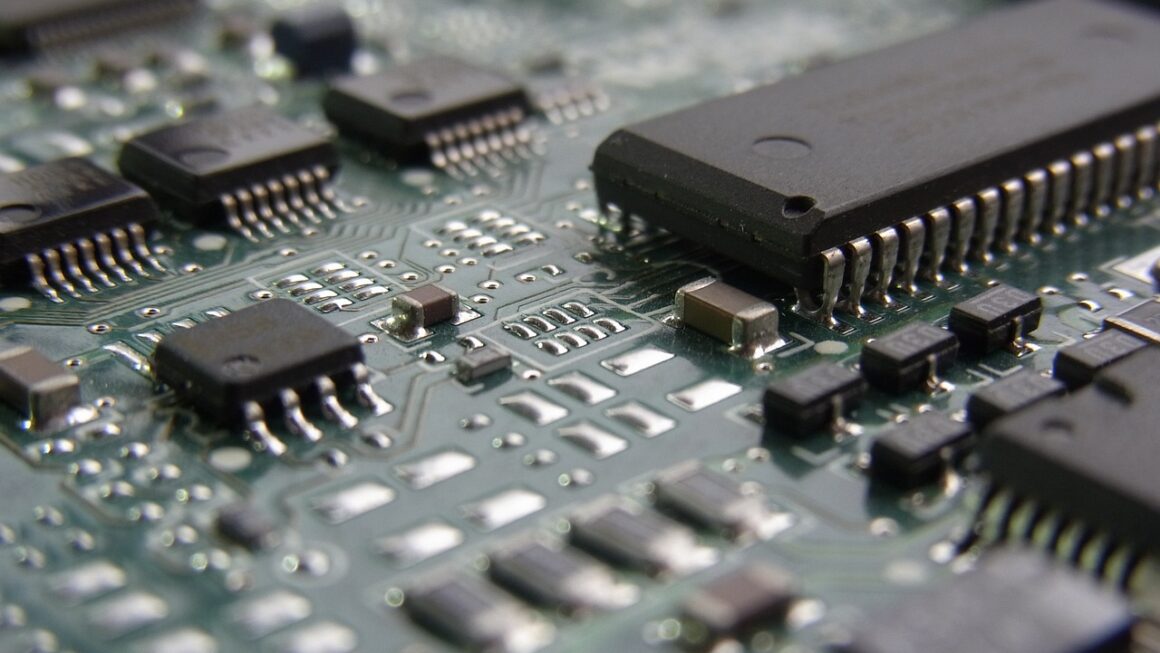

Semiconductors, often called microchips or integrated circuits, are the invisible engines driving our modern world. From smartphones and laptops to cars and medical equipment, these tiny components are the foundation of nearly every electronic device we rely on. Understanding semiconductors is crucial for anyone interested in technology, business, or the future of innovation. This article will delve into the world of semiconductors, exploring their functionalities, manufacturing processes, and the crucial role they play in our lives.

What are Semiconductors?

The Basics of Semiconductor Materials

Semiconductors are materials that have an electrical conductivity between that of a conductor (like copper) and an insulator (like rubber). This unique property allows them to control the flow of electricity, making them essential for electronic devices. The most common semiconductor material is silicon (Si), but other materials like germanium (Ge) and gallium arsenide (GaAs) are also used.

- Silicon (Si): Abundant and relatively inexpensive, silicon is the workhorse of the semiconductor industry.

- Germanium (Ge): While it was used extensively in early transistors, germanium is now less common due to its temperature sensitivity.

- Gallium Arsenide (GaAs): Offers higher electron mobility than silicon, making it suitable for high-frequency applications.

How Semiconductors Work

The magic of semiconductors lies in their ability to be selectively doped with impurities. This process, called doping, introduces atoms with either extra electrons (n-type semiconductors) or fewer electrons (p-type semiconductors) into the semiconductor material. When p-type and n-type materials are joined, a p-n junction is formed, creating a diode. Diodes allow current to flow in only one direction. Transistors, which are the building blocks of modern integrated circuits, use multiple p-n junctions to amplify or switch electronic signals.

- N-type semiconductors: Doped with elements like phosphorus or arsenic, which have extra electrons.

- P-type semiconductors: Doped with elements like boron or gallium, which have fewer electrons (creating “holes”).

- Transistors: Can act as switches or amplifiers, controlling the flow of current.

The Semiconductor Manufacturing Process

From Silicon Wafer to Microchip

The process of manufacturing semiconductors is incredibly complex and requires highly specialized equipment and cleanroom environments. Here’s a simplified overview:

Key Manufacturing Technologies

Several key technologies are critical to semiconductor manufacturing:

- EUV Lithography: Extreme ultraviolet (EUV) lithography uses very short wavelengths of light to create extremely fine features on the chip, enabling the production of smaller and more powerful transistors. Companies like ASML are the leading providers of EUV lithography equipment.

- Chemical Vapor Deposition (CVD): Used to deposit thin films of various materials onto the wafer.

- Ion Implantation: A precise method for introducing dopant atoms into the semiconductor material.

- Cleanroom Environment: Semiconductor manufacturing requires extremely clean environments to prevent contamination, as even tiny particles can ruin the chips.

Applications of Semiconductors

Powering the Modern World

Semiconductors are the backbone of countless industries and applications:

- Consumer Electronics: Smartphones, laptops, tablets, smartwatches, and gaming consoles all rely heavily on semiconductors for processing power, memory, and communication.

- Automotive Industry: Modern cars use semiconductors for engine control, infotainment systems, safety features (like airbags and anti-lock brakes), and autonomous driving technologies. The increasing complexity of automotive electronics is driving significant demand for semiconductors.

- Healthcare: Medical devices such as MRI machines, pacemakers, and diagnostic equipment use semiconductors for data processing, imaging, and monitoring.

- Industrial Automation: Semiconductors are used in robots, sensors, and control systems to automate manufacturing processes and improve efficiency.

- Renewable Energy: Solar panels and wind turbines use semiconductors to convert sunlight and wind into electricity.

- Aerospace and Defense: Semiconductors are critical for navigation systems, communication systems, and weapons systems.

Emerging Technologies

Semiconductors are driving innovation in several emerging technologies:

- Artificial Intelligence (AI): AI algorithms require powerful processors and memory chips to handle the massive amounts of data involved in training and inference.

- 5G and Wireless Communication: 5G networks rely on advanced semiconductors for high-speed data transmission and low latency.

- Internet of Things (IoT): IoT devices, such as smart home appliances and wearable sensors, use low-power semiconductors to collect and transmit data.

The Global Semiconductor Industry

Key Players

The semiconductor industry is dominated by a few key players:

- Intel: A major manufacturer of CPUs and other microprocessors.

- Samsung: A leading producer of memory chips (DRAM and NAND flash) and mobile processors.

- TSMC (Taiwan Semiconductor Manufacturing Company): The world’s largest dedicated semiconductor foundry, manufacturing chips for other companies.

- SK Hynix: Another major player in the memory chip market.

- Micron Technology: Specializes in memory and storage solutions.

- Qualcomm: Known for its mobile processors and wireless communication chips.

Geopolitical Considerations

The semiconductor industry is becoming increasingly important from a geopolitical perspective. The concentration of manufacturing in certain regions, particularly Taiwan, raises concerns about supply chain security. Governments around the world are investing heavily in domestic semiconductor manufacturing to reduce their reliance on foreign sources.

- The CHIPS and Science Act in the United States provides billions of dollars in funding for semiconductor manufacturing and research.

- The European Union is also investing in domestic semiconductor production.

Conclusion

Semiconductors are fundamental to our modern technological landscape. Understanding their function, manufacturing, and applications is essential for navigating the complexities of our increasingly digital world. As technology continues to evolve, the demand for more advanced and efficient semiconductors will only grow, driving further innovation and shaping the future of numerous industries. By grasping the core concepts and following the trends in this vital field, you can gain a valuable perspective on the forces shaping our lives and the future of technology.

Read our previous article: Beyond Automation: Digital Transformations Human Renaissance

Beyond the Screen: Augmented Reality’s Spatial Computing Leap

For more details, visit Wikipedia.